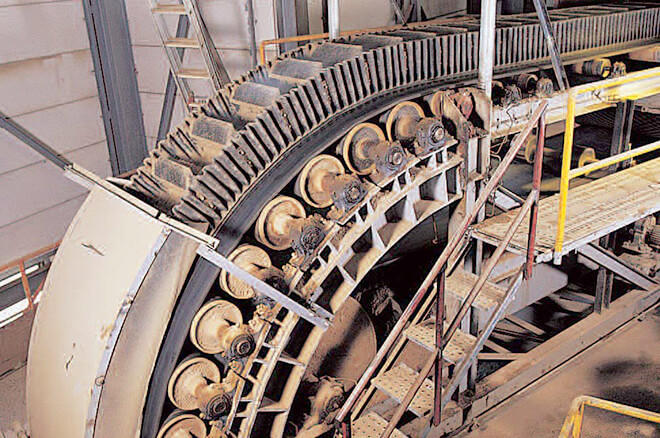

How Corrugated Sidewall Belts Improve Material Handling Efficiency

Corrugated sidewall belts are an advanced type of conveyor belt with an integrated corrugated sidewall along the length of the belt. The corrugated sidewall also helps to reduce friction on the belt, which increases the speed of the conveyor. This means that materials can be moved more quickly, and with less effort. Sidewall conveyor belts are easy to install and maintain, which can help to reduce operational costs.

Image Source: Google

The corrugated sidewall also allows for more efficient material handling. By using the sidewall to move the material, there is less need for additional labor or machinery to move and organize the material. This makes it easier and faster to move materials around a facility.

The corrugated sidewall also helps to reduce the amount of dust and debris that is created by the movement of material. The sidewall helps to contain the material and keep it in place, which prevents it from being scattered around the facility. This helps to reduce the risk of airborne dust and the associated health hazards.

Overall, corrugated sidewall belts are an excellent choice for efficient material handling. They are more durable than traditional flat belts and can move materials up steep inclines with a greater load capacity. They also help to reduce dust and debris, which increases safety and efficiency.